Changes happen frequently in the world of manufacturing - engineers should utilize tools that are simple yet, can handle complex design issues.

With the innovation that keeps on being developed today, all tedious tasks involved in product development can all be handled with great ease.

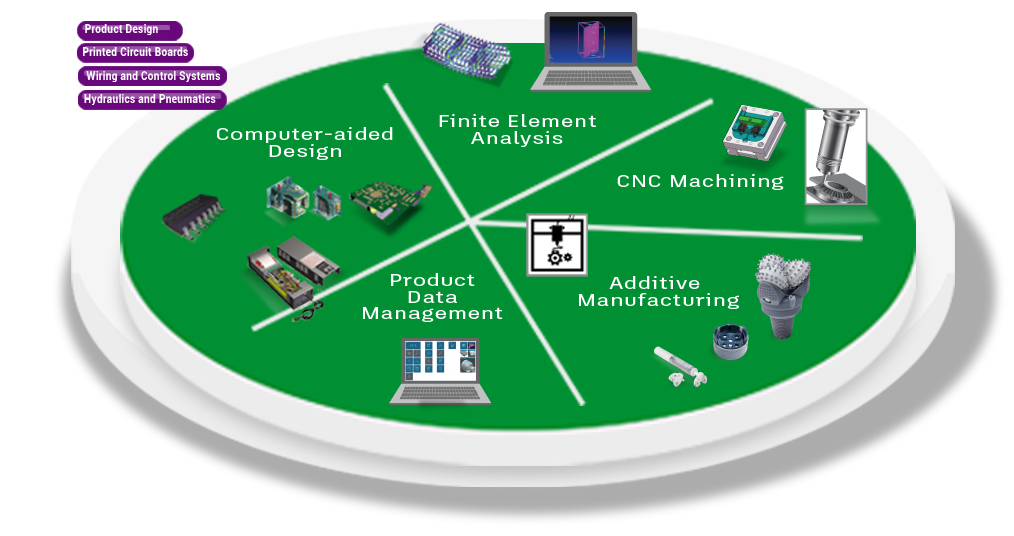

Design

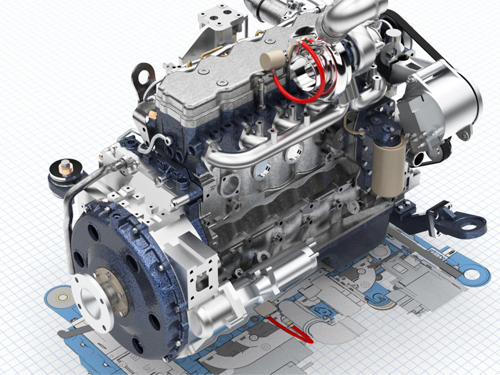

The future of 3D product development is here already. Before getting to the latter steps of product development, the design- aesthetics, functions, parts, and holistic properties, are to be treated with extensive planning and collaboration. And we have to do this fast.

Synchronous Technology, a unique capability of one of Siemen's solutions for Product Development helps designers to design better products better than other 3D product design solutions can. It helps designers to prevent pre-planning, failures, rebuilding and rework through simultaneous updates to all multiple parts in an assembly and flexible direct modelling.

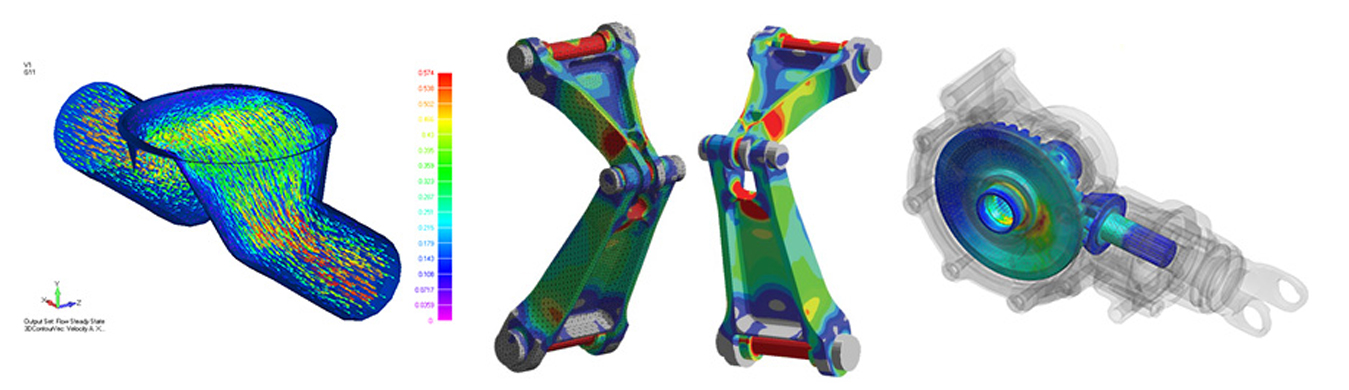

Finite Element Analysis (FEA)

What is FEA?

Finite Element Analysis is a way of predicting how a product reacts to natural, man-made or real-world influences or for a particular environment such as heat, mass transport, and electrostatics. This will determine if you have designed your product right.

With conducting FEA, you can:

- Predict and improve product performance and reliability

- Avoid time-consuming and costly continual prototyping and testing

- Evaluate and explore different designs and materials

- Optimize design and reduce material usage

A closer look always shows the vulnerabilities of the product. And in able to have accurate finite element models, and advanced simulation software must be utilized.

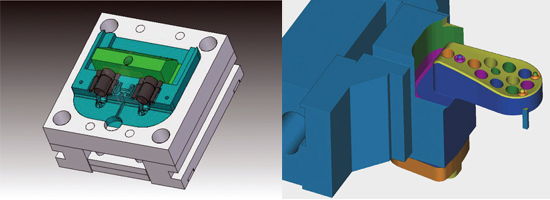

CNC Machining

In deep contrast with manual machining, CNC requires digital data in controlling and monitoring movements of the machines.

To strive in a competitive market, manufacturers should maximize the most efficient Computer Aided Manufacturing (CAM) software as this will be very l incremental in the significance of the machine tools that you will be investing in- this could be milling machine, broaching machine, drill press, hone, lathe, screw machines and a lot more.

CAD programming/ machining requires deep knowledge and mastery that's why it's important to manufacturers to invest in efficient and easy to use CNC programming tool that has capabilities for the different NC machining procedures:

- Drilling

- 2 1/2 Axis Milling

- Turning

- 3 Axis Milling

- Wire EDM Programming

- Machining Simulation

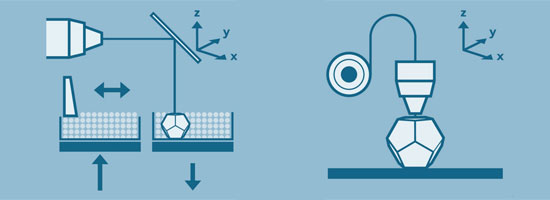

Additive Manufacturing

Though the idea of additive manufacturing was introduced 30 years ago, manufacturers are adapting the process in product development during the past few years.

In a study conducted in 2014, the additive manufacturing industry grew by 35.2 %, being widely used in manufacturing and construction industries.

As innovative enhancements are being done year by year, 3D printers are now made more affordable and functional than ever, disrupting the way manufacturers develop their products.

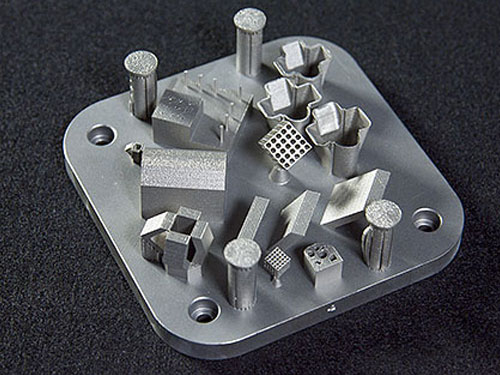

1. Revisions made easier, less cost, less time

Creating prototypes, parts and molds usually take months, but thanks to 3d printing this process could take just a few days.

This is not limited to producing one part but producing numerous versions simultaneously. Engineers now can study a lot of versions without the constraints of the old industrial processes.

2. Prototyping to Producing Real Parts and Products

It's just a matter of years when 3d printers could produce large-scale supplies of real parts and products.

Imagine printing product parts exactly what you need, and when you need them. With the various materials that are being maximized now and the advancements in crafting 3d printers- Desktop Printers, SLA, Digital Light Processing and many more, additive manufacturing could be of great to real production.

Same goes with machines with parts that are no longer in production. With 3D printing, all you got to do make 3d design files of the part that are needed and proceed to 3d printing.

In the medical field, the first ever 3d stent implant was done last February. The patients who received the new implants are having no side effects as of now and if situation retains like this for the rest of time, this will be considered as a major breakthrough in 3D printing.

3. Is your Product Good Enough?

3D printing is a method that is very beneficial in progressive research of your product- improvement from time to time. Take full advantage of the benefits of 3D printing and increase efficiency of your products. With 3D printing making all research processes a lot easier.

One of the best ways in exploring your design is by studying it closely, by having actual precise models of it.

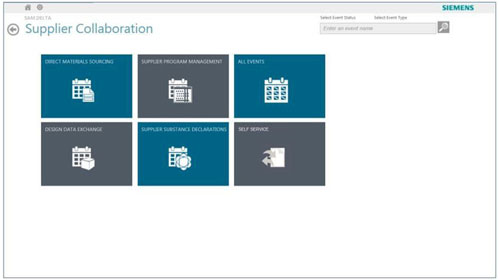

Product Data Management (PDM)

Product development doesn't end with your design.

It's paramount to secure and get control of all engineering documentation along your product and process data during and even after the design process.

Your PDM system should be able to manage all Computer Aided Design (CAD)data, models, parts information and documents on one secured system that can be also be accessed by all teams working across the organization.

Main Functions:

- File ownership, Version Control (check-in and check-out of files) and Revision Management

- Establishment, management, and execution of workflow-driven processes for change planning, incorporation, verification and communication

- Management and presentation complete BOM (Bill of Materials)

- If you collaborate effectively and have the access to the right data at the right time, you could reduce cycle time, cost and errors. Remember that we all live in a dynamic era now, and we must adapt dynamic ways to be able to keep up.